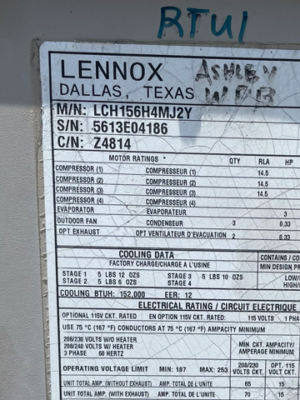

Address the inherent leakage problems found in Lennox’s LCH156H4 rooftop unit and other original equipment manufacturer (OEM) MCHX coils with a cost-effective microchannel conversion solution. When it comes to replacing commercial condenser coils, the Lennox LCH156H4 is a frequent contender. This unit often requires attention due to its all-aluminum microchannel design, which has been a standard feature in many air conditioning systems for over a decade, not just limited to Lennox units but across most OEM equipment. The microchannel coils offer cost savings by utilizing aluminum as a cheaper alternative to traditional materials, while simultaneously reducing the refrigerant footprint. However, these advantages come with notable drawbacks. One of the key downsides of microchannel coils is their susceptibility to dirt accumulation, similar to the lint trap in a dryer. Without regular maintenance, this can lead to increased head pressure, causing operational inefficiencies. Furthermore, precise refrigerant charging is critical for optimal performance, given the low refrigerant volume in MCHX coils. Repairing an aluminum microchannel coil is also challenging, often requiring specialized techniques such as two-part epoxy or torch soldering. During repairs, aluminum is particularly vulnerable to environmental factors, and leaks at the copper-to-aluminum connections are quite common. Switching Gears: Upgrading to a Copper Tube, Aluminum Fin Coil A superior alternative to the microchannel design is the high-grade copper tube, aluminum fin coil—a microchannel conversion that not only enhances the performance of your Lennox unit but also boosts its reliability and longevity. This upgrade offers several benefits: Finishing the Conversion When switching from microchannel condenser coils to copper tube coils, completing the refrigeration circuit is essential. For instance, if a Lennox LCH156H4 unit has eight microchannel coils divided into two circuits of four each, and only one coil is faulty, all four coils in that circuit must be replaced to ensure proper operation. This is because copper tube coils use a different refrigerant pressure drop compared to microchannel coils, and mismatching them could lead to operational issues. Additionally, the total refrigerant capacity required differs between the two types, necessitating a full circuit replacement for compatibility. #ExpertsInMicrochannelConversion While the Lennox LCH156H4 rooftop unit is among the more commonly serviced models requiring microchannel conversion, this upgrade is applicable to virtually any major commercial HVAC brand. Over the years, we've successfully completed thousands of conversions, establishing ourselves as the go-to experts in microchannel transformations. If you're considering this advantageous upgrade, feel free to reach out to us. Simply provide the unit's make and model number, and our team will guide you through the process. Contact us at 1.888.CoilPro or email us anytime—we’re here to help! Glass Bonding,Uv Bonding Glass,Uv Curing Adhesive Glass Bonding,Uv Bonding Glue Guangdong Shengtang New Material & Technology Co.,Ltd. , https://www.shengtang-silicone.comTransforming the Microchannel Coil in the Lennox® LCH156H4: Enhancing Performance and Reliability