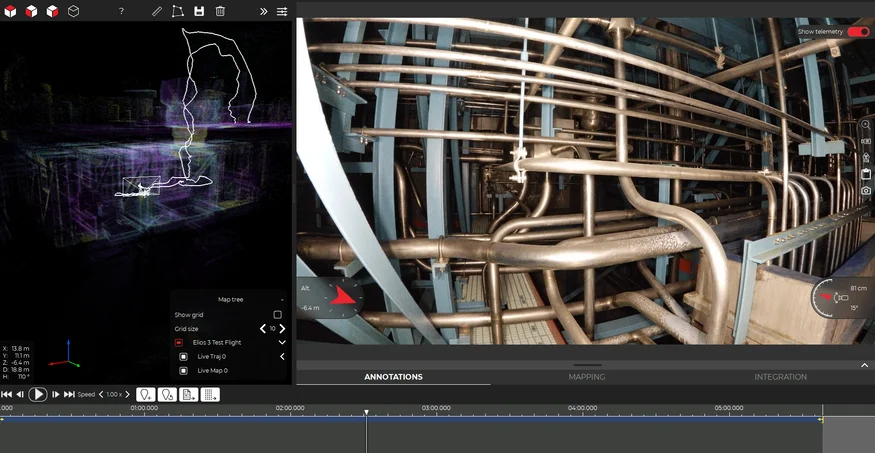

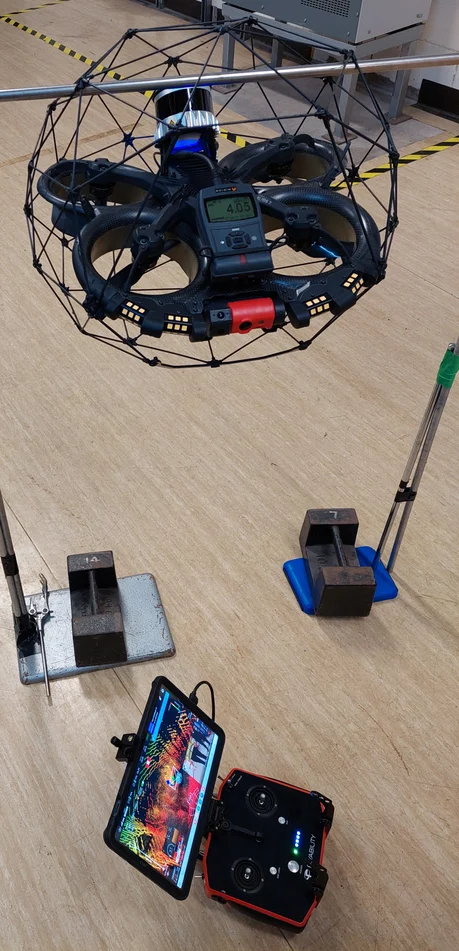

In this exclusive interview, we speak with Amanda Smith, the UAV equipment programme manager at Sellafield, to learn how drones are transforming safety and efficiency at one of the world’s most complex nuclear sites. Sellafield, once known as Windscale, is located on the Cumbrian coast in the UK. It was a functioning nuclear power plant until 2003 and is now home to one of the largest and longest-running decommissioning projects globally. The site spans nearly six square kilometers and includes its own fire service, medical team, and a wide range of departments. Amanda Smith leads the UAV equipment programme at Sellafield, which is part of the Engineering and Maintenance Profession. This initiative is a key component of the specialist equipment services, contributing to the broader efforts of the 3,500 employees working on the site. Amanda shares insights into how drones have become an essential tool for inspections, enhancing safety, speed, and cost-effectiveness.  I've been managing the UAV programme at Sellafield for about four years. Before that, I had no direct experience with drones, but I recognized their potential early on. As an electrical engineer, it was a steep learning curve, but we quickly built a strong foundation for our drone operations. Today, we conduct routine flights and use drones for various inspections. We're also exploring the integration of radiation detection systems with drones in the future, which could further enhance our capabilities. Sellafield is more than just a nuclear site—it's like a small town. It has its own infrastructure, including a fire department and medical team, and is part of the Nuclear Decommissioning Authority (NDA), a government initiative focused on cleaning up the UK’s early nuclear sites. We collaborate with other NDA sites, sharing best practices and lessons learned. For example, our team has supported drone operations at Bradwell and Sizewell. My role involves testing new technologies and assessing their suitability for our unique environment. Our first tests with drones were conducted by an external contractor who demonstrated their value. After evaluating the applications, we decided to build an in-house programme. It took six months to get approval for our first flight, as we had to set up processes, follow strict regulations, and gain support from multiple teams. Our initial focus was on security and resilience, but the programme expanded significantly after 2020, with over 200 asset inspection flights completed in 2021. Screenshot from an inspection completed with an Elios drone at Sellafield As of 2023, I manage four equipment engineers who are also remote pilots. They handle everything from selecting the right drones to conducting maintenance and writing operational guidelines. Our drones are monitored through rigorous maintenance schedules. We also have an emergency duty team that operates year-round, ensuring continuous support even during holidays. Annually, we complete at least 200 flights with the core team. While we started with external inspections, we are now seeing a major increase in internal inspections using visual data, 3D models, and LiDAR scans. Working in radioactive or contaminated environments presents several challenges. We distinguish between radiation and contamination, both of which are common at Sellafield. Contamination is particularly difficult to manage. Once a device becomes contaminated, it can’t be removed from the area unless it’s thoroughly decontaminated. Loose contamination, such as radioactive dust, can easily accumulate on drones, especially on parts like propellers and cages. However, the inner components of the motors cannot be accessed, so once a drone enters a contaminated area, it remains there. We can change batteries and collect data, but we must operate within the contaminated space. In areas with high levels of loose contamination, flying a drone may stir up dust, potentially exceeding regulatory limits. In such cases, we avoid using drones to ensure compliance and safety. The RAD payload is designed for remote radiation detection and localization. It uses an RDS-32WR sensor by Mirion Technologies. Our proof-of-concept test aimed to evaluate the performance of the Elios 3 and RAD payload in a radiological survey. We created a controlled environment with sealed sources and dummy sources to avoid bias. A pilot flew the Elios 3 with the RAD payload, looking for radiation spikes to create a heat map of the area. Amanda Smith along with representatives from Flyability and Coptrz This project involved collaboration with the remote technologies group, radiometrics systems group, and representatives from Flyability and Coptrz. Early results were promising—our tests showed that the RAD could detect elevated radiation levels and identify high-sealed sources in separate rooms. We will continue testing to refine flight techniques and assess the sensor’s performance in different environments, helping us define the optimal use cases for the RAD payload. The Elios 3 RAD includes an RDS-32WR sensor by Mirion Technologies (image courtesy of Coptrz) Elios drones have become an integral part of our operations. The RAD payload is especially exciting as it aligns with our goals of improving safety, speed, and cost-efficiency. Here are some key benefits: Safety: Drones allow us to conduct pre-surveys before sending personnel into high-risk areas, reducing exposure and freeing up staff for higher-priority tasks. Speed: We can deploy drones rapidly, providing real-time data that improves situational awareness and decision-making. Cost: By avoiding scaffolding and reducing time spent on inspections, we save significant resources. We estimate saving around £5 million annually through drone use alone. Beyond radiation detection, we use Elios drones for internal inspections, such as checking pipe hangers and crane elements. The cage design ensures safe operation near critical infrastructure without risking damage. We plan to expand our use cases continuously. While we started with reactive responses, we are now conducting regular inspections. Every project often opens up new opportunities, and we’re always looking for ways to improve. The modular system of the Elios 3 is very promising. We’re currently testing the RAD payload, but the LiDAR payload has already shown great potential. A recent LiDAR scan was used to create a 3D-printed model of a site element, demonstrating the value of this technology. We are also investing in pilot training, ensuring they understand all aspects of drone operation. As we refine our methods, we aim to make every task safer, faster, and more cost-effective. A big thank you to Amanda Smith and Tom Calverley for their time and insights. Learn more about Sellafield on the UK Government website. Discover more about the Elios 3 and its applications Dripper Type Irrigation Pipe Making Machine

Description:

PE layflat drip irrigation water hose is used for drip irrigation.

Watering and fertiliaing the crops in the same time.It can improve the use ratio of fertilizer.

High pressure resistance: Made from new PE material (high strength PE woven fabric+PE sheet, new technology)

Features:

Cutting down production costs.

Decreasing damage from insects.

Increasing productivity.

Made of superior high-strength PE.

Excellent Elongation performance in length & diameter

Flexible, economical and practicable with a single wall thickness 0.2-0.65mm.

Application:

PE hose is widely used for green house,fruit trees,field crops and so on.

It is also ideal for auxiliary equipment in agriculture and forestry irrigation and is fit for conveying liquid at low or medium temperature.

It can reduce more than 20%-30% humidity of air and decrease the insect disaster.Increasing 2-3℃ of the earth temperature.Making the crops ripe 7-15 days in advance.

Dripper Irrigation Pipe Making Machine,Dripper Irrigation Pipe Making,Dripper Irrigation Pipe Machine,Dripper Type Irrigation Pipe Making Machine KonRun Intelligent Machinery(Ningbo) Co., Ltd. , https://www.konrunmachine.comInterview: Elios Drones at Sellafield, Europe's Largest Nuclear Site

Tell Us About Your Background. Did You Work With Drones Prior To Starting The Sellafield UAV Program?

Tell Us About Sellafield - What Are You Doing There?

Amanda has been in charge of the UAV programme at Sellafield for about 4 yearsHow Would You Describe The Sellafield UAV Programme?

How Are You Using Drones In Radioactive Or Contaminated Environments? We've Heard About Radioactive Dust - Could You Tell Us More About That And What Challenges You Face?

You Have A Substantial Fleet Of Elios Drones From Flyability. This Year, We Launched The Elios 3 Drone Along With The RAD Payload Specifically For Use In The Energy Industry. In July 2023, You Had A Proof Of Concept For This Payload. What Was The Process?

What Are Your Thoughts On Working With Elios Drones In These Use Cases?

The Elios 3 RAD in testing at SellafieldSo, What's Next For Your Drone Fleet At Sellafield?