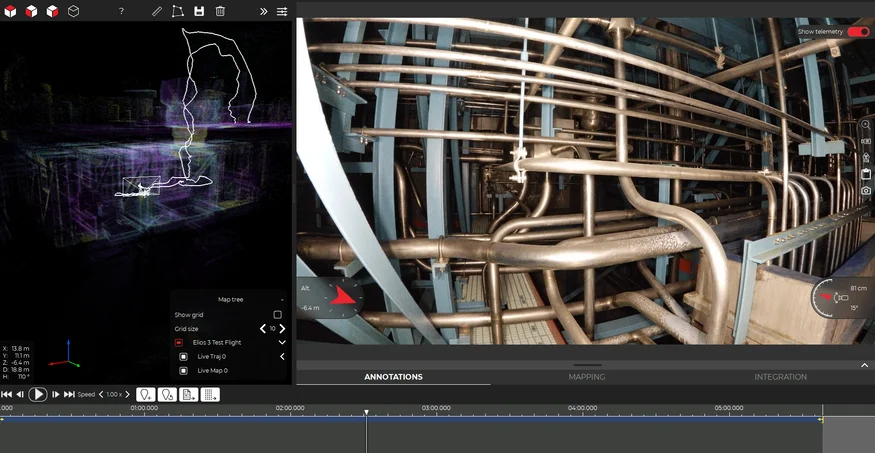

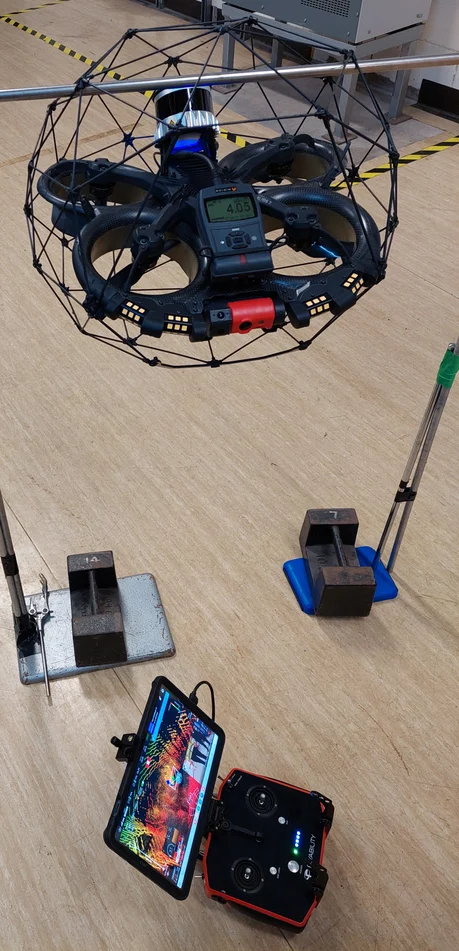

In this exclusive interview, we sit down with Amanda Smith, UAV equipment programme manager at Sellafield, to explore how drones are transforming safety and efficiency at one of the world’s most complex nuclear sites. Sellafield, formerly known as Windscale, is a sprawling site on the Cumbrian coast in the UK. It operated as a nuclear power plant until 2003 and now serves as the epicenter of one of the largest decommissioning projects globally, expected to span several decades. Amanda Smith leads the UAV equipment programme at Sellafield, part of the Engineering and Maintenance Profession. This initiative is among many projects run by the 3,500-strong team at the site. She shares insights into how drones have become an essential tool for inspections, improving safety, speed, and cost-effectiveness. Her journey from an electrical engineer with no drone experience to leading a successful UAV program has been nothing short of transformative. I've been managing the UAV program at Sellafield for about four years. Before that, I had no direct experience with drones. However, my team recognized the potential value they could bring to our operations. As an electrical engineer, it was quite a learning curve, but now we conduct flights regularly, and drones have become a key part of our inspection process. We're even exploring future uses like radiation detection with drones. Imagine a small town spread over six square kilometers—this is Sellafield. It has its own fire department, medical team, and numerous departments. As part of the Nuclear Decommissioning Authority (NDA), we're responsible for cleaning up early UK nuclear sites. We collaborate with other NDA sites, sharing best practices and lessons learned. Our team has supported drone operations at locations like Bradwell and Sizewell. Part of my role involves testing new technologies and assessing their suitability for our site. We don’t just look at the tech itself but also the companies behind it, helping shape future products to better suit our needs. Our initial tests with drones were done through an external contractor who showed us the basics. After evaluating the applications, we decided to build an in-house program. Getting approval for the first flight took six months due to the need for proper processes and safety protocols. Initially, we focused on security and resilience. By 2020, we expanded to over 200 asset inspections. Now, we have more than 20 drones and 20 pilots. Screenshot from an inspection completed with an Elios drone at Sellafield Today, I directly manage four engineers who are also remote pilots. They handle everything from selecting the right drones to writing maintenance guides. We monitor each drone through strict schedules. In addition, there's an emergency duty team that works year-round, even during holidays. We conduct at least 200 flights annually with the core team. While we started with external inspections, internal ones are increasing rapidly. We use visual inspections, 3D models, and LiDAR scans. With the Elios 3 RAD, we’re looking forward to unlocking new possibilities after testing. We face several challenges, especially with contamination. Unlike radiation, which can be measured, contamination is harder to manage. If a device is contaminated, it can't be removed without thorough cleaning. Loose contamination, such as radioactive dust, is particularly problematic because it can settle on drones and be hard to clean off, especially inside motors. Once a drone enters a contaminated area, it stays there. Additionally, flying drones in areas with high levels of loose contamination can disturb the dust, potentially causing it to exceed regulatory limits. In such cases, we avoid using drones altogether. The RAD payload is a specialized sensor that can be mounted on the Elios 3. It detects and localizes radiation using the RDS-32WR sensor from Mirion Technologies. Our goal was to test the Elios 3 and RAD in a radiological survey workflow. We set up a testing area with sealed sources and dummy sources to avoid bias. A pilot flew the drone, and we looked for radiation spikes to create a heat map. The results were promising: the RAD detected elevated radiation levels, including a high source in a separate room. Amanda Smith along with representatives from Flyability and Coptrz This project involved collaboration between our team, the radiometrics group, and Flyability and Coptrz. Early results indicate success. We will continue testing to refine techniques and understand the sensor’s performance in different environments. The Elios 3 RAD includes an RDS-32WR sensor by Mirion Technologies (image courtesy of Coptrz) We already use Elios drones across many projects. The RAD payload is particularly exciting because it supports our goals of working safer, faster, and cheaper. In terms of safety, drones allow us to enter hazardous areas before humans, reducing risk. They also enable quick access to contaminated zones. Speed is another benefit—our pilots are always on call, and data is available almost instantly. Cost savings come from avoiding scaffolding and saving time, with estimates showing around £5 million saved annually. We inspect pipe hangers, crane elements, and other critical infrastructure. The Elios 3’s LiDAR scanner is especially useful for creating detailed 3D models. The modular system opens up new opportunities for future payloads. We are continuously expanding our use cases. Each project often leads to new ideas. As we train more pilots and optimize our operations, we remain committed to making tasks safer, faster, and more efficient. A big thank you to Amanda Smith and Tom Calverley for sharing their insights. Learn more about Sellafield on the UK Government website. Discover more about the Elios 3 and its applications Other Profile Extrusion Line PVC Decoration Sheet

YF series PVC imitation Marble (Foam) Profile Extrusion Line, consists of single screw extruder and the special co-extruder,with the cooling water tank, hot stamping machine system, hual-off unit, and stacker. This line with imported ABB AC inverter control, imported RKC temperature meter etc. and features of good plasticization, high output capacity, and stable performance etc. By adjust the embossing wheel the machine can work on various of different profiles. Working together with the main extruder and other extrusion down steam equipments, this line is popular ad the latest developed producing line.

UV Imitation Marble Board:

a. Board surface coat imitation marble film, or laminate imitation marble and through curing treatment, good anti scratch, and scratch resistance.

b. Board with variety of color, it is convenient to construct.

c. Instead of marble etc. natural stone in the interior.

Pvc Sheet Extrusion Line,Pp Sheet Extrusion Line,Pc Sheet Production Line,Sheet Extruding Production Line KonRun Intelligent Machinery(Ningbo) Co., Ltd. , https://www.konrunmachine.comInterview: Elios Drones at Sellafield, Europe's Largest Nuclear Site

Tell Us About Your Background. Did You Work With Drones Prior To Starting The Sellafield UAV Program?

Tell Us About Sellafield - What Are You Doing There?

Amanda has been in charge of the UAV programme at Sellafield for about 4 yearsHow Would You Describe The Sellafield UAV Programme?

How Are You Using Drones In Radioactive Or Contaminated Environments? We've Heard About Radioactive Dust - Could You Tell Us More About That And What Challenges You Face?

You Have A Substantial Fleet Of Elios Drones From Flyability. This Year, We Launched The Elios 3 Drone Along With The RAD Payload Specifically For Use In The Energy Industry. In July 2023, You Had A Proof Of Concept For This Payload. What Was The Process?

What Are Your Thoughts On Working With Elios Drones In These Use Cases?

The Elios 3 RAD in testing at Sellafield