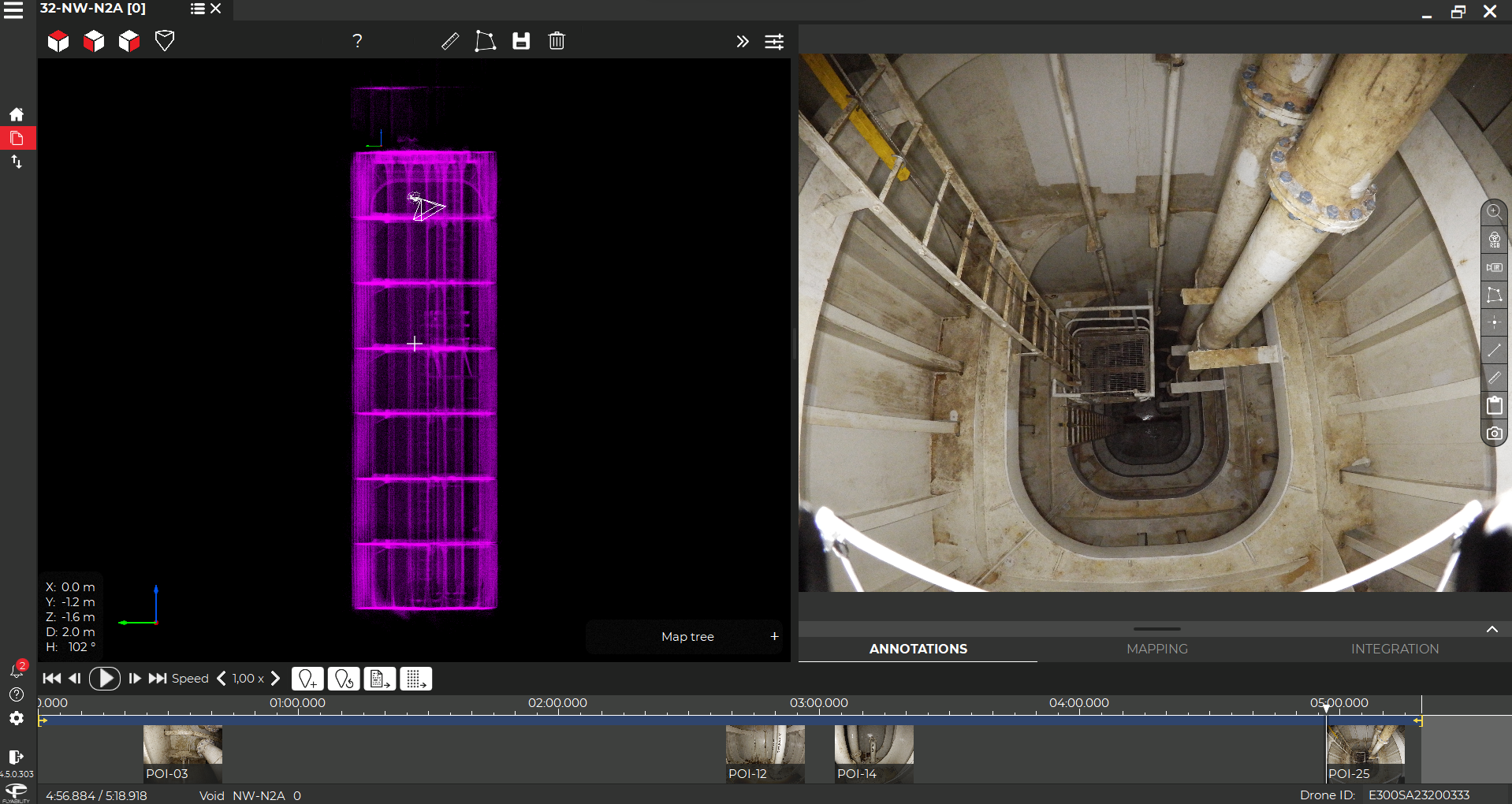

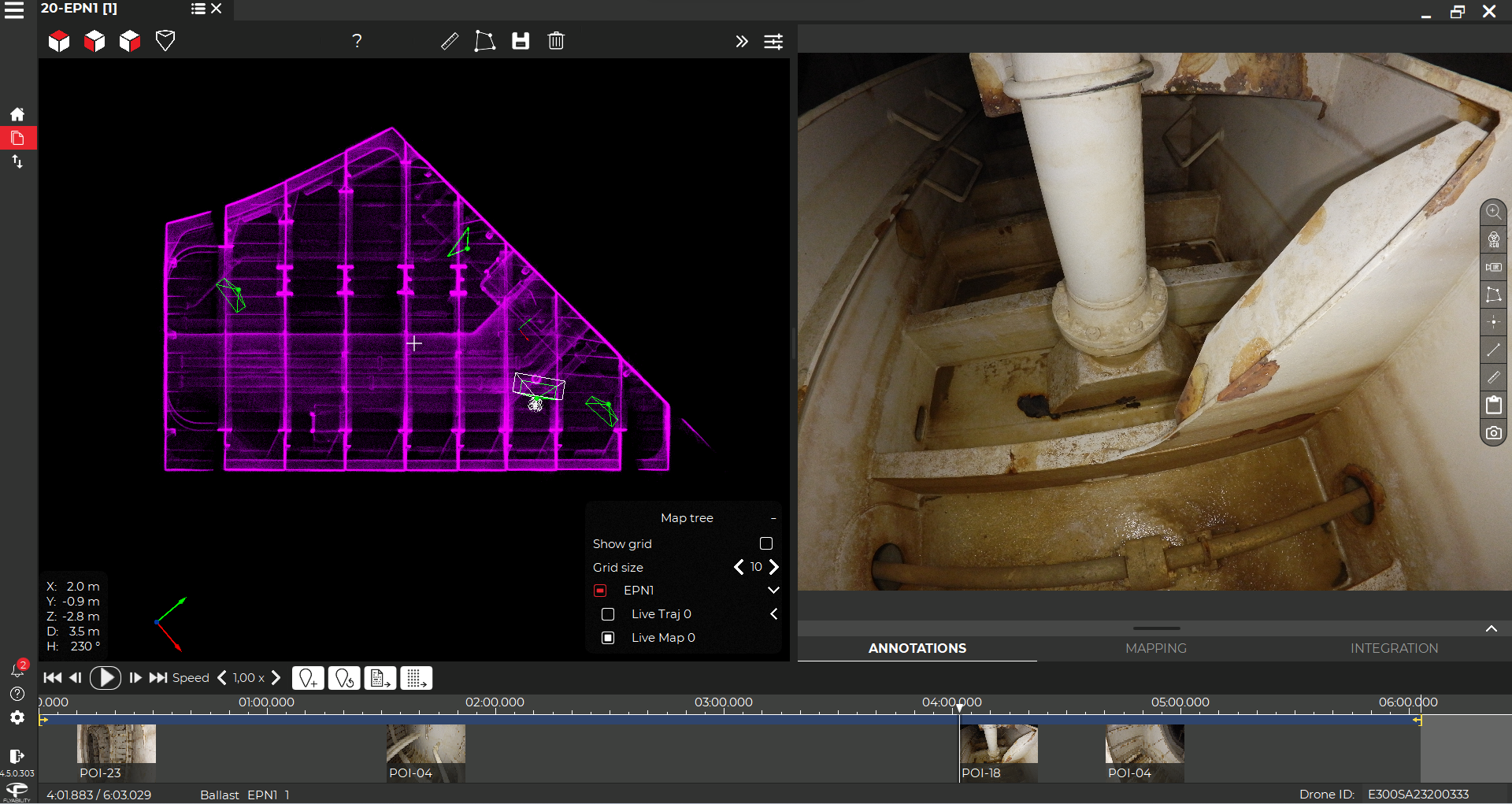

Elios drones helped TDBR Inspections transform the process of tank inspections at the 3R-2 rig located off the coast of Brazil. Speed Using Elios 2 and Elios 3 drones, TDBR Inspections managed to inspect 63 tanks in just two weeks with only two team members. Previously, this task would have taken months and required three or more staff members. Safety With drones, there was no need to send personnel into the tanks or perform tasks at heights. Since no human entry was required, there was no need for special permits, making the entire operation smoother and safer. Accuracy The results obtained during these inspections were shared with the Class Society, which sets standards for maritime and drilling equipment. Every single result from the Elios 2 and Elios 3 met the required class standards. Efficiency By completing inspections with drones, the number of people on board (PoB) at the rig remained within limits and was better optimized, allowing engineers and workers to be present instead of inspection teams.   Working offshore presents unique challenges. Equipment failures or delayed deliveries can lead to extended downtimes or potential risks. Balancing inspection and maintenance with operational procedures and site efficiency is crucial. For the 3R-2, a TLWP-type oil rig off the coast of Brazil, major inspections pose significant challenges. The rig has a maximum PoB of around 60 people. These 60 individuals include engineers, operators, and general staff. Staff are transported to the rig by helicopter, so optimizing the PoB and managing their transportation on and off the platform helps streamline work without overburdening staff or straining operations. The tanks being inspected are extremely tall, making manual inspections difficult. However, inspecting assets like tanks onboard can be challenging. The 3R-2 has several large tanks, and inspecting each one requires multiple staff members using ropes, taking several days per tank. As the facility is ten years old and adheres to high regulatory standards, all inspections must be thorough to update existing records. The question is: is there a way to achieve these results without bringing large teams of inspectors on board for extended periods? Finding this balance optimizes PoB while streamlining inspections and data management. TDBR Inspections, a drone service provider in Brazil, has extensive experience conducting complex inspections with the Elios drone. They were approached by Raul Martini, a naval engineer specialist from 3R Petroleum , who owns the 3R-2. Their goal was to use the Elios drone for tank inspections to see if they could save time at the rig. The aim was to collect visual data regarding the condition of the large tanks. TDBR Inspections needed to create an archive of relevant images for visual inspections, defect checks, and fault identification. Areas of concern could then be marked with special paint to highlight areas requiring attention. The project was massive, with over 70 tanks at the site. TDBR Inspections planned to visit 3R-2 four times to gather data. The key advantage of using the Elios drone was the time and cost savings, along with simplified logistics. Entering a tank of this size for inspection requires a special permit, but a drone needs no such authorization. Additionally, the results were to be submitted to the Class Society to verify accuracy. If successful, this project could lead to a potential partnership between TerraDrone and 3R Petroleum to regularly conduct inspections on 3R-2 using the Elios drone. A team from TDBR Inspections traveled to the 3R-2 and began planning their flight routes. This was part of Phase 1 of the project. They conducted reconnaissance flights with an Elios 2 to scout the tanks and plan asset entry. Inside a ballast tank visualized with the Elios 3.  After some initial external inspection flights as part of Phase 1, the TDBR Inspections team returned a month later to start Phase 2. During that month, they purchased an Elios 3 and brought both the Elios 2 and Elios 3 to the 3R-2. Over the span of 14 days, TDBR Inspections' pilots completed 88 separate flights around 63 tanks. The total flight time exceeded 10 hours, involving both the Elios 2 and Elios 3. After the flights were finished, the data was processed using Inspector 4. Visual inspections from both drones were used to update existing records and search for anomalies, while the LiDAR data from the Elios 3 was utilized to create 3D models of the inside of the tanks. These models provided clear insights into the tanks' conditions, enabling detailed knowledge of the assets without anyone entering the confined spaces. This project's scale is unprecedented—inspecting 63 tanks in just two weeks meant the team was inspecting over 10 assets daily. This is far more efficient than traditional methods. For instance, on an FSPO, tank inspections require up to 4 or 5 rope access technicians, taking up to a week to complete. With an Elios 3, it took only 2 people just 2 days per tank. Looking ahead, TDBR Inspections anticipates repeating inspections of this kind at 3R-2 and other similar sites. Their operational efficiency brought significant time and cost savings to the managers at 3R-2, optimizing the movement of staff and inspectors, thus addressing the PoB challenge. Not only did the Elios keep people safe and out of confined spaces, but it also collected data that met the regulatory requirements of the Class Society, solving a real-world industry problem. Learn more about the Elios 3 and its applications. Seat Storage,Car Seat Back Storage,Car Seat Storage,Car Netting Bag Ningbo Yonghai Auto Products Co., Ltd. , http://www.yonghai-manufacturer.comInspection of 63 Tanks Using Two Drones in Just Two Weeks

Key Benefits at a Glance

Customer Needs: Complex Inspections for an Offshore Rig

Solution: Drone Inspections to Save Time

The Elios 2 (top) and Elios 3 (bottom) outside the narrow tank entry points.

The Elios 2 (top) and Elios 3 (bottom) outside the narrow tank entry points.Results: Inspecting 63 Tanks in 88 Flights

Conclusion: A Long-Term Strategy for Faster Rig Inspections