Safety Unknown conditions in the underground galleries made data collection challenging due to potential hazards like exposed wiring, old equipment, or dangerous materials. The Elios 3 provided a safe alternative to traditional inspection methods by reducing the need for human entry into these risky environments. Speed The use of the drone allowed for fast and efficient data collection across multiple galleries. It adapted well to different site conditions, streamlining the process of mapping over 13 kilometers of underground spaces, including confined areas, open zones, and around pipe racks. Data Quality The Elios 3, equipped with a LiDAR payload, was used over 9 intense days to conduct 241 flights. From these, 1,776 points of interest were recorded and analyzed by experts to assess the condition of the galleries. Access The underground galleries are spread throughout the city, some of which had water pooling or very tight spaces. The Elios 3 proved highly adaptable, capable of being deployed in a wide range of environments, making it ideal for this complex project. Brussels is a major European city, home to the European Commission and hosting a large international community alongside a vibrant business and cultural scene. Known as the "Capital of Europe," it's an ideal location for developing smart city initiatives. Smart cities leverage technology to collect data and optimize urban operations, from smart traffic systems to eco-friendly architecture. A successful smart city relies on a combination of advanced tech, system optimization, and comprehensive asset management. To improve the management of its underground infrastructure, the Maintenance and Inspection Department at Brussels Mobility launched a project to survey and map technical galleries beneath the city. Many of these galleries were built decades ago without up-to-date records, so the goal was to create a detailed inventory of their current state to support future maintenance and space utilization planning. The presence of the underground galleries was known, but their exact locations, sizes, and connections were not. Brussels Mobility aimed to create an accurate record of these spaces to better manage them. With no existing designs to reference, they needed to build a detailed as-built model of the network. Brussels Mobility partnered with several companies to form a specialist team. They needed experts in data collection and processing who could safely access unknown and potentially hazardous areas. SECO, an engineering and construction firm, was the first partner, tasked with inspecting concrete structures and collecting data. They brought in a specialized drone inspection partner to assist with the project. Sweco, a leading engineering and architecture consultancy, joined the effort to create an inventory of the underground utility structures. They used LiDAR and visual imagery to generate detailed 2D maps and 3D cross-sections of the sites. Medexon and Flywel, two drone inspection companies in Belgium, also joined the project. Their fleet included the Elios 3, a drone designed for navigating hazardous and confined spaces. They were asked to help scout areas before human entry and inspect dangerous locations. With this experienced team in place, the project began. Image right: The Elios 3 and its Surveying Payload enabled safer and faster data collection compared to traditional methods, allowing teams to explore difficult-to-reach areas efficiently. The data collection team had three main objectives: The team faced various challenges, including electrical hazards, blocked passages, and difficult environmental conditions. To navigate these, they relied heavily on the Elios 3 for both scouting and data collection. Despite cold temperatures, the team conducted over 200 flights using the Elios 3 to gather LiDAR and visual data across 13 kilometers of underground spaces. The data was georeferenced to create a final, accurate map of the entire network. The Elios 3’s Surveying Payload was especially useful for tackling tough locations like storm drains. In some cases, the team manually held the drone to capture LiDAR data where flying wasn’t possible. This flexibility helped ensure comprehensive coverage of even the most challenging spots. Want to learn more about the Elios 3, its Surveying Payload, and how it reduces drift? Check out our accuracy report. Over the course of the project, the team successfully mapped 13 kilometers of underground spaces, including storm drains, technical rooms, and galleries. The work involved 241 flights over nine intensive days, during which 1,776 points of interest were identified and recorded. Data processing and mapping were significant tasks, with some challenges related to LiDAR drift. However, through collaboration with the Flyability team, the results were optimized. Sweco created a detailed LiDAR map overlaid with surface data, providing a clear view of underground assets in relation to the surrounding environment. This helps planners identify access points and plan future maintenance more effectively. This project has been ongoing for over a year, with continuous collaboration among all the teams involved. It has proven to be a huge success in gathering comprehensive and actionable data for Brussels Mobility, helping them plan the future of these underground spaces. In the future, Brussels Mobility hopes to share this data with utility companies to aid in maintenance and repairs, as well as use the maps to explore new public uses for the galleries. Drones like the Elios 3 have made underground surveys faster and safer, whether in mines, sewers, or technical galleries. Its ability to collect data and provide situational awareness ensured the safety of the team, even in GPS-denied environments. Medexon-Flywel is confident in the drone’s capabilities for future similar projects, especially with the new Surveying Payload. Discover more about the Elios 3 and its specialized LiDAR payload. All images in this article are credited to CLP Power. Double Water Cooling Roller,Water-Cooled Roller With Guide Tube,Aluminum Foil Coating Line Water Cooling Roll,Cast Hearth Roller For Steel Mill Jiangsu Kinuo Furnace Roller Co., Ltd. , https://www.jskinuoroller.comMapping 13 Kilometers of Underground Technical Galleries in Brussels

Key Benefits at a Glance

Building a Specialized Underground Survey Team

Underground Surveys Using the Elios 3

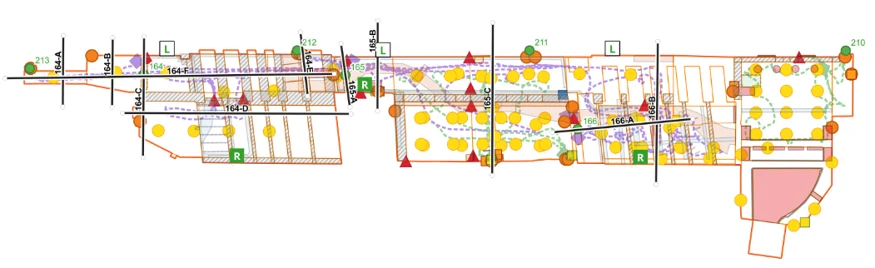

Surveying 13 Kilometers with the Elios 3

The gallery maps are accurately referenced and ready to support maintenance efforts.

The gallery maps are accurately referenced and ready to support maintenance efforts.