The term "mining tools" broadly encompasses all the equipment and machinery utilized in the extraction of minerals from the earth. From the cars we drive to the electronics we use daily, minerals are integral to countless consumer products. Essential resources like uranium and coal, which provide nearly half of the United States' energy needs, originate from mining operations. All of these valuable resources are accessed through the application of various mining tools and equipment. Before delving into the specifics of mining tools and equipment, it's vital to understand the different mining techniques employed. This guide begins by outlining the primary methods of mining—underground, open surface (pit), placer, and in-situ mining. Each technique influences the type of tools and machinery required. Generally, the mining process follows a standardized sequence: extraction, material handling, and processing. Extraction involves digging, drilling, or blasting into the earth to retrieve minerals. Material handling focuses on sorting and directing the targeted minerals toward processing sites, while irrelevant materials are sent to waste areas. Finally, material processing involves refining the minerals into finished goods for distribution. Mining can be categorized into four main types: underground, open surface (pit), placer, and in-situ mining. The type of material being extracted and the chosen mining technique directly affect the selection of mining tools. While the fundamental steps remain consistent for surface and underground mining, the methods vary depending on the terrain and material being mined. Surface mining is ideal for minerals located near the earth's surface. Common surface mining techniques include strip mining, open pit mining, quarrying, in-situ leach (ISL) mining, and placer mining. Strip mining removes layers of overburden (soil and rock) to access minerals, often preparing the area for open-pit mining. Open-pit mining involves drilling and blasting to create pits for accessing underlying rocks, useful for extracting materials like silver. Quarrying extracts hard stones like granite and marble, facilitated by open-pit mining. In-situ leach mining targets minerals like uranium, dissolving them in place without disturbing surface layers. Placer mining uses pans and water to separate gold from sand and gravel based on its higher density. Some minerals necessitate underground mining due to their depth below the surface. This method requires specialized equipment and techniques to navigate confined spaces. Underground mining includes blast mining, room and pillar mining, retreat mining, block caving, cut and fill mining, drift and fill mining, longwall mining, shrinkage stope mining, and sublevel caving. Each technique serves a unique purpose, such as supporting the mine's ceiling in room and pillar mining or extracting steeply dipping ore bodies in sublevel caving. Distinct mining tools are used for soft and hard rock mining. Soft rock mining relies on specialized machinery, while hard rock mining employs explosives and hydraulic drills. Soft rock minerals like salt, coal, bauxite, and potash can be extracted without explosives, whereas hard rock minerals such as copper, gold, iron, and uranium require blasting. Hydraulic drills play a crucial role in creating holes for explosives in hard rock mines. While numerous mining tools exist, we categorize them here by mining method for better comprehension. This approach allows us to explore the tools tailored to specific mining techniques. In addition to standard mining tools, miners rely on personal protective equipment (PPE) to ensure safety. Key items include air respirators for clean air, cap lights for visibility, hearing protection for noisy environments, miner's pouches for tools and safety devices, protective communication devices, reflective clothing for visibility, and self-rescuers for emergencies. Each piece of PPE plays a critical role in maintaining miners' safety during operations. Surface mining employs a variety of equipment tailored to its specific needs. Blasthole drills are used to create holes for explosives, while bucket-wheel excavators efficiently dig, transport, and load materials. Dozers move earth, dragline excavators remove overburden, and graders construct roads for efficient transportation. Highwall miners extract coal from exposed seams, and mining trucks, including autonomous models, transport minerals. Shovels and wheel tractor scrapers further aid in excavation and material movement. Drones assist in overground surveys and inspections, offering enhanced safety and efficiency. Underground mining demands specialized equipment designed for confined spaces. Crane lifts handle heavy loads, continuous miners automate coal extraction, and jumbo drills create holes for explosives or mine shafts. Loaders and haulers efficiently move materials, while longwall mining machines build tunnels. Refuge chambers provide safety in emergencies, and roof bolters secure mine ceilings. Scoops transport minerals, shotcrete machines reinforce tunnel walls, and ventilation systems maintain breathable air. Underground rails facilitate the movement of miners and materials, ensuring smooth operations. Additional tools are essential for both surface and underground mining, including hoppers, chutes, conveyor belts, stackers, reclaimers, feeders, crushers, mills, screens, roasters, mixers, and agitators. These tools facilitate material transport and processing, ensuring efficient operations. As the mining industry evolves, integrating advanced technologies like drones and LiDAR is becoming increasingly important. Drones, particularly those equipped with LiDAR, offer safer alternatives for inspections and surveys, reducing risks and enhancing productivity. Despite its ancient origins, the mining industry continues to adapt and innovate. Emerging technologies are transforming how mines are documented and surveyed, making operations safer and more efficient. The integration of drones and LiDAR in mining underscores the industry's commitment to modernizing processes while preserving its legacy of resource extraction.  Extrusion aluminum radiators are a type of radiator made from extruded aluminum. These radiators are designed to provide efficient and effective cooling for a variety of applications, including automotive, industrial, and residential heating and cooling systems.The extrusion process used to manufacture these radiators involves forcing heated aluminum through a die to create a specific shape. This process results in a radiator with a uniform and consistent shape, which helps to improve its performance and durability.One of the key benefits of extrusion aluminum radiators is their high thermal conductivity. Aluminum is an excellent conductor of heat, which means that these radiators can quickly and effectively transfer heat away from the source and into the surrounding environment. This makes them ideal for use in high-performance applications, such as racing cars and industrial machinery.Another advantage of extrusion aluminum radiators is their lightweight and durable construction. Aluminum is a lightweight material that is also highly resistant to corrosion and other forms of damage. This means that these radiators can withstand harsh environments and provide reliable performance over a long service life. Extrusion Aluminum Radiator,Extruded Aluminum Radiator,Extruded Tube Radiator,Extrusion Aluminum Heat Sink Radiator Suzhou Remgar Metal Manufacturer Co.,Ltd. , https://www.remgaral.comMining Equipment: A Comprehensive Guide to Tools and Machines

Types of Mining Methods

Surface Mining Methods

Open-pit mine | Source: ​​Adam Rhodes on Unsplash

Open-pit mine | Source: ​​Adam Rhodes on UnsplashUnderground Mining Methods

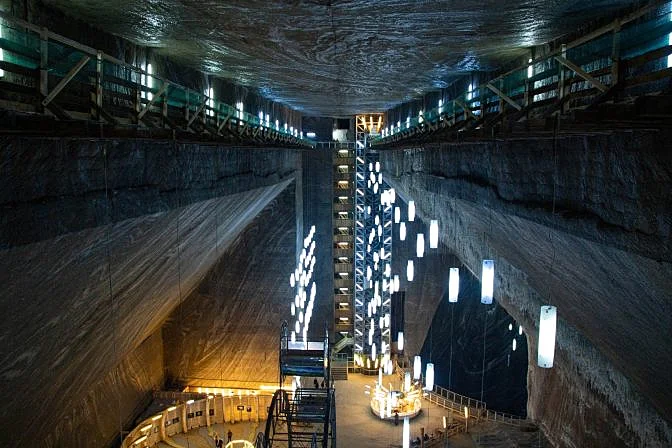

Salt mine | Source: Szabolcs Molnar from Pixabay

Salt mine | Source: Szabolcs Molnar from PixabayMining Equipment for Soft Rock vs. Hard Rock Mines

Mining Tools and Equipment

Mining Personal Protective Equipment (PPE)

Surface Mining Equipment

Blasthole drill | Source: Cat Models

Blasthole drill | Source: Cat ModelsUnderground Mining Equipment

Elios 3 drone | Source: Flyability

Elios 3 drone | Source: FlyabilityOther Mining Tools

Overall, extrusion aluminum radiators are a versatile and effective cooling solution for a wide range of applications. Whether you need to cool an engine, a computer, or a building, these radiators can provide the performance and reliability you need to keep your equipment running smoothly.