Auto Spare Parts Near Me,Auto Spare Parts And Accessories,Silicone Car Molds Molds,Car Door Panel Mould Weifang Yida Mould Co.,Ltd , https://www.wfyidamold.com

Independent power producers (IPPs) operate under various business models when acquiring solar assets. Some focus on developing projects from the ground up, including site selection and initial design studies, while others prefer to purchase PV systems that are already under construction. There are also IPPs that specialize in acquiring fully operational solar facilities. Regardless of their approach, all these activities require engineering support—whether for the project owner or the lender—to ensure successful execution and reduce risk.

The primary objective of engineering services provided by an owner’s engineer (OE) or independent engineer (IE) is to de-risk the investment. This involves identifying and addressing potential issues, as well as validating the project’s performance against its original model. The earlier Pure Power is involved as an OE or IE, the more value we can add to the project. Early engagement allows us to optimize the project’s design, avoid costly rework, and align the project with financial and technical goals.

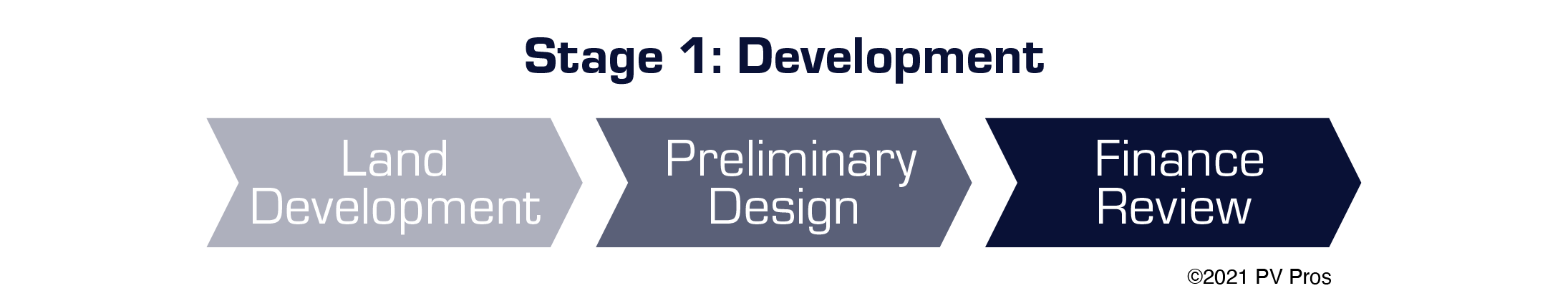

In this first part of a two-part article, I will explore how third-party engineering services can be optimized during the development and pre-construction phases of a solar project.

**Engaging an Owner’s Engineer During Development**

For IPPs that plan to own the project long-term, it's crucial to involve an OE early in the development process. Once a suitable land parcel is identified, an OE can provide essential preliminary design services, such as due diligence and technical assessments.

**Due Diligence**

Early-stage due diligence focuses on reviewing the preliminary design, identifying deficiencies, and eliminating potential issues before construction begins. At this stage, the project team defines the AC and DC nameplate capacity and starts specifying major equipment. It’s also an opportunity to optimize the system design, helping the owner meet or exceed financial targets. This ensures that non-recurring engineering budgets are spent wisely on viable projects.

An experienced OE with solar expertise can identify design flaws in equipment layout and utilization, reducing risks before detailed engineering begins. They also ensure the project meets interconnection requirements and validate the accuracy of the PVsyst model, providing a finance summary report to confirm realistic energy generation estimates.

**Technical Services**

De-risking assets during development also requires detailed planning and contracts based on industry standards. When engaged early, Pure Power offers foundational support that sets the project up for success. These efforts not only aid in evaluating and selecting EPC contractors but also protect the owner from construction defects and poor performance.

**Engaging an Owner’s Engineer During Pre-Construction**

For IPPs with long-term ownership plans, skipping engineering support during pre-construction is a costly mistake. An OE can significantly enhance the project’s design, especially in the early stages. As discussed in a previous blog post about the "cost of quality," the closer a project gets to completion, the more expensive it becomes to fix issues. The ability to correct problems, find value engineering opportunities, or adjust contracts diminishes once drawings or specifications are issued for permits or bidding.

**Design Review**

The design phase typically includes three key drawing sets: 30% for interconnection applications, 60% for permitting, and 90% for procurement. Fixing issues at the 30% stage is far less costly than during construction or operations. Even at the 60% stage, there are still opportunities to correct design flaws before they become embedded in the final build.

**Value Engineering**

Beyond fixing issues, an experienced OE can also spot value engineering opportunities during the design phase. These may include reducing construction costs, increasing energy output, or accelerating the project timeline—all of which enhance the asset’s value.

**Planning and Standards**

During pre-construction, setting clear expectations and establishing baselines is critical. As outlined in a previous post on capacity testing to ASTM 2848, not all performance protocols are equal, especially from the perspective of an at-risk owner. Engaging an OE early helps identify and eliminate gaps in design standards, contract terms, or testing procedures that could shift risk onto the long-term owner. Therefore, it's important to involve an OE before sending out design drawings for permits, bids, or procurement.