A self-moving scissor fork type lift platform is a type of lifting equipment that is designed to provide vertical access for people and materials in various industrial and commercial settings. It consists of a scissor mechanism that extends and retracts to raise and lower a platform, which is mounted on a set of forks. This design allows for easy maneuverability and flexibility in reaching different heights and locations. Mobile Scissor Lift Platform,Self-Propelled Platform Lift,Mobile Hydraulic Lift Platform,Hydraulic Lift Porema (Suzhou) Logistics Machinery and Equipment Co., LTD , https://www.jsporema.comUnderstanding the Different Types of Pipes and Fittings for Compressed Air Systems

Pipes and fittings are essential elements in a compressed air system. They act as the backbone that connects all the components together. Properly installed and maintained pipes ensure that the compressed air system operates at peak efficiency. Poor-quality pipes, on the other hand, can lead to significant energy loss, blockages, and even safety hazards.

One of the most critical aspects of a compressed air system is ensuring that the pipes are appropriately sized. An undersized pipe can significantly reduce the airflow and pressure, making the system inefficient. Additionally, factors like moisture buildup, sharp bends, and obstructions can further compromise the system's performance. Therefore, selecting the right type of pipe material is crucial for maintaining the integrity and longevity of your compressed air system.

There are several types of pipes commonly used in compressed air systems. Each has its own set of advantages and disadvantages depending on the specific needs of your application.

The Two Main Categories of Pipes for Compressed Air Systems

The primary materials used in pipes for compressed air systems are plastic and metal.

Plastic Pipes

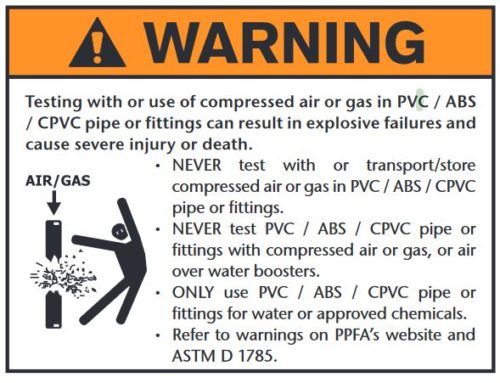

Plastic pipes offer excellent resistance to corrosion, which means they are less prone to rust and blockages. Their smooth interior promotes laminar flow, reducing turbulence and friction within the pipe. Among the plastic options, acrylonitrile butadiene styrene (ABS), polyethylene (PE), and high-density polyethylene (HDPE) are considered ideal for compressed air systems. However, PVC pipes are strongly discouraged due to their tendency to degrade over time. Not only do they pose a safety risk, but using PVC in compressed air systems also violates OSHA regulations.

Metal Pipes

Metal pipes remain the go-to choice for many industrial applications due to their durability and strength.

- **Black Steel Pipe**: This is a popular choice because of its robustness. However, black steel pipes require more maintenance due to their susceptibility to corrosion. Threaded connections may also loosen over time, leading to leaks.

- **Galvanized Steel Pipe**: Galvanized steel offers better protection against corrosion compared to black steel. Yet, the zinc coating might flake off, potentially causing blockages in the air stream.

- **Copper Pipe**: Copper pipes are lightweight, easy to cut and solder, and provide excellent corrosion resistance. They feature a smooth interior, ensuring consistent airflow. Additionally, copper has a wide variety of fittings available, making it versatile for various applications.

- **Aluminum Pipe**: Aluminum pipes are lightweight, corrosion-resistant, and easy to handle. Their fittings are straightforward to assemble, making installation quicker and more efficient.

- **Stainless Steel Pipe**: Stainless steel pipes are highly durable and resistant to both corrosion and degradation. While they are more expensive, their ability to withstand extreme conditions makes them suitable for demanding environments. However, their weight can make them challenging to install, limiting their popularity in certain applications.

Fittings for Compressed Air Systems

Fittings play a vital role in ensuring seamless connections between pipes. Push-in fittings, in particular, are favored for their ease of use. You can quickly connect and disconnect lines without requiring tools. Our extensive range of fittings includes bulkhead unions, male and female elbows, connectors, and unions. Available in materials such as nickel-plated brass, steel, and nylon-plated brass, these fittings cater to diverse requirements. The quick-connect design allows for rapid assembly, saving valuable time during installation. Moreover, these fittings are reusable, enabling multiple connections without compromising performance.

Why Choose the Right Pipes and Fittings?

Selecting the appropriate pipes and fittings is essential for maintaining optimal performance in your compressed air system. A well-designed system ensures reliability, reduces downtime, and minimizes maintenance costs. At Compressed Air Systems, we specialize in providing high-quality pipes, fittings, and accessories tailored to meet your specific needs. Whether you're upgrading an existing system or starting from scratch, our team is here to assist you in choosing the best solutions for your business.

If you need more information about the different types of pipes and fittings for compressed air systems, feel free to reach out to us. We’re always happy to help you find the perfect solution to keep your system running smoothly and efficiently.

---

At Compressed Air Systems, we pride ourselves on offering comprehensive support for all your compressed air needs. From initial consultation to ongoing maintenance, our experts are committed to helping you achieve maximum efficiency and productivity. Don't hesitate to contact us today to learn how we can enhance your compressed air system!

The self-moving feature means that the lift platform can be driven and operated by the user, eliminating the need for external power or assistance. It typically includes a control panel or joystick that allows the operator to control the movement of the lift, such as raising and lowering the platform, steering, and driving.

The scissor fork type lift platform is commonly used in warehouses, distribution centers, manufacturing facilities, construction sites, and other locations where there is a need for efficient and safe vertical access. It can be used for tasks such as stock picking, maintenance and repair work, installation of equipment, and general material handling.

Safety features are an integral part of self-moving scissor fork type lift platforms. These may include emergency stop buttons, safety rails, non-slip platform surfaces, overload protection, and proximity sensors to prevent collisions with obstacles.

Overall, a self-moving scissor fork type lift platform provides a versatile and practical solution for vertical access needs, allowing users to efficiently and safely reach various heights and locations within a facility.