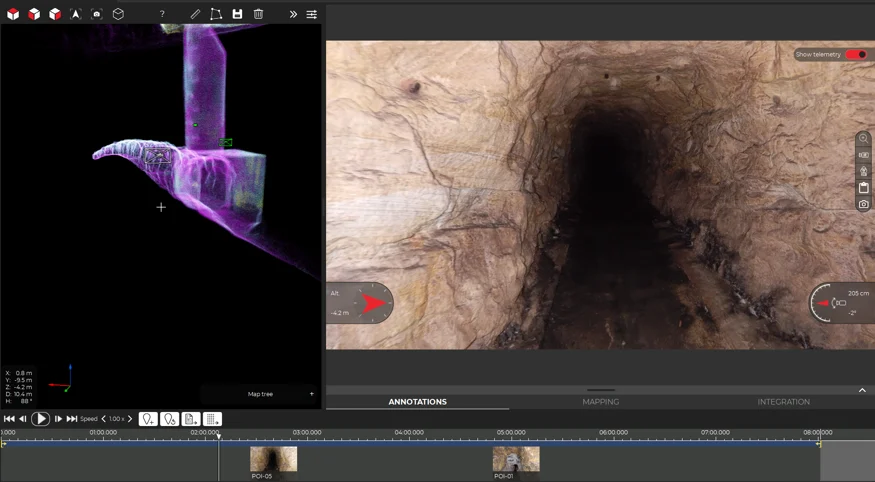

Safety Surveyors, engineers, and asset inspectors can collect data with confidence while avoiding risks such as falls from height, exposure to hazardous gases, tunnel collapse, and being engulfed by wastewater. Data Quality The drone enables Metrocorp to gather high-quality LiDAR data along with visual imagery, resulting in detailed 3D point clouds and photogrammetry models that offer a clear view of underground structures. Efficiency The Elios 3 completed a 175-meter unsupported rock tunnel inspection in just two flights, taking under 30 minutes—compared to up to 2 hours previously. Drone inspections also require 90% less documentation, significantly speeding up the process. Cost Savings Remote inspections reduce time and personnel needed during planning and on-site work, potentially cutting project costs by 50% to 70%. Metrocorp Technologies has over 30 years of experience delivering complex projects and achieving outstanding results for their clients. Based in Australia, they work across the country on wastewater, stormwater, and remediation projects in collaboration with engineering and surveying firms. Recently, they adopted the Elios 3 to make underground and confined space inspections safer, faster, and more efficient. Working with sewers and wastewater systems presents unique challenges. Blockages, floods, and aging infrastructure can all complicate operations. When Metrocorp collects data in these environments, they must ensure accuracy while following strict safety procedures. In Sydney, efforts are underway to rehabilitate aging wastewater structures to extend their service life by another 50–100 years. This includes analyzing existing records, mapping unused areas, and planning maintenance and upgrades. However, condition assessments are especially difficult because they often need to be done while the system is still in operation. Metrocorp has identified four key hazards during sewer inspections: To address these risks, Metrocorp uses the Elios 3 drone to collect data from a safe distance. In one recent project, the drone inspected four 17-meter-deep tunnels showing signs of severe deterioration. A team of just three people completed the task in a single day, whereas a traditional method would have required at least seven to ten people and multiple shifts. Metrocorp was tasked with assessing an old, deep wastewater access shaft as part of an ongoing inspection program. Traditionally, inspecting a 70-meter-deep shaft involves setting up specialized equipment and sending one person down for a visual check. This approach carries significant risks, including falls, exposure to hazardous gases, and potential injury from falling objects. With the Elios 3, these risks are eliminated. The drone captures high-resolution images and LiDAR data, which can be analyzed remotely from the office. This not only improves safety but also provides accurate measurements that help asset owners plan rehabilitation strategies. The Elios 3’s LiDAR payload created a precise 3D point cloud model, which was used by the asset owner to understand the structure better. Additionally, video footage from two flights was used to generate a 3D photogrammetry model, giving engineers a full view of the tunnel's dimensions and internal features. The entire inspection was completed in under 30 minutes, saving 3 hours compared to traditional methods. “Entering a high-risk asset in Sydney can take weeks of planning. The drone can go without the same level of scrutiny and delivers higher quality data,†said Metrocorp. The use of drones in sewer inspections is becoming increasingly common due to their ability to operate in harsh conditions and reduce risk exposure. Metrocorp has seen significant improvements in efficiency, cost savings, and safety through the use of the Elios 3. The Elios 3 offers enhanced safety, improved efficiency, and higher quality data, reducing the cost of sewer inspections by up to 40% per linear meter. With the release of the Surveying Payload in 2023, data accuracy and quality have further increased. Learn more about the Elios 3 and its advanced LiDAR capabilities today. Powder sintered filter, stainless steel powder sintered filter, metal powder sintered filter, copper powder sintered filter, stainless steel sintered filter Xinxiang Zhike Machinery Equipment Co.Ltd , https://www.zhikefilter.comBringing Safer Confined Space Sewer Inspections To Sydney With The Elios 3

Key Benefits At A Glance

The Challenges Of Water And Wastewater Inspections

The Metrocorp team follows strict safety protocols during sewer and confined space inspections

Using The Elios 3 For Deep Manhole Condition Assessments

The Elios 3 makes underground tunnel inspections safer and more data-richUsing The Elios 3 For Sewer Inspections

Sintered filter element: It is a new type of filter material made of multi-layer metal sintered mesh, using multi-layer stainless steel mesh pressed by special lamination and sintered by vacuum with high strength and overall rigidity.

peculiarity

1) High strength: After five layers of wire mesh sintering, it has extremely high mechanical strength and compressive strength;

2) High precision: uniform surface filtration performance for 2-200um filter particle size;

3) Heat resistance: can be durable from -200 degrees to 650 degrees of continuous filtration;

4) Cleaning: Due to the use of excellent counter-current cleaning effect of the surface filter structure, cleaning is simple.

Main use

1) Used as dispersion cooling material in high temperature environment;

2) For gas distribution, liquid bed hole plate material;

3) For high precision, high reliable high temperature filtration materials;

4) For high pressure backwash Oil Filter.

The sintered stainless steel filter element can not only be used as the filter medium of the filter equipment such as basket filter and mesh filter, but also because the sintered stainless steel filter element has many excellent properties such as high filtration accuracy, high temperature resistance, corrosion resistance, high mechanical strength, easy processing and long life, so it is more and more used in the separation field of products and process media in the petroleum and petrochemical industry.