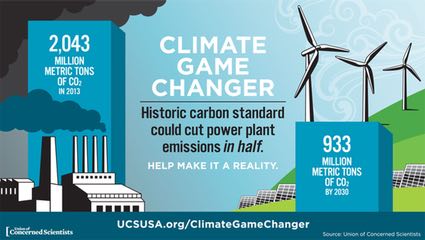

Enhancing Mine Safety Through Advanced Proximity Detection Systems Every day, mine workers confront tough and frequently dangerous situations. Surface mines, marked by massive machinery with restricted visibility, create scenarios where detecting smaller vehicles and pedestrians becomes challenging, heightening the risk of accidents and injuries. Underground mines, with their confined spaces and proximity challenges, are further complicated by elements like dust, insufficient lighting, and heavy machinery. According to data from the CDC's Office of Mine Safety and Health Research, from 2000 to 2007, more than 40% of the most severe mining injuries—those resulting in fatalities or permanent disabilities—were due to collisions, pinning, crushing, and striking incidents. To address this, the Mine Safety and Health Administration (MSHA) has proposed new regulations requiring the installation of Proximity Detection Systems on continuous mining machines. Proximity Detection Systems leverage cutting-edge technology that could save lives. These systems use various warning tools, including radar, sonar, GPS, and cameras, to alert mine operators when someone or something enters the path of a mining machine. When this happens, the system immediately halts the machine's operation. Such systems are increasingly being installed on mining equipment globally, proving to be invaluable in both surface and underground mines. Although MSHA has approved several commercially available systems, their criteria primarily focus on the systems' spark and thermal ignition safety rather than their performance. Mining has always been one of the world's most hazardous occupations. Even with enhanced safety standards, laws, and innovative equipment, mining accidents still happen. The Office of Mine Safety and Health Research reports: HJ3 is dedicated to providing the industry’s most resilient carbon fiber solutions, and our mission is to improve safety across various sectors. With advancements in safety equipment and dependable structural repair systems, the prospect of eliminating mining accidents is becoming increasingly feasible with each passing day. As we continue to push for technological innovation, it’s crucial to remember the broader implications of our work. Beyond enhancing mine safety, these technologies also contribute to global efforts to reduce carbon emissions. Each state in the U.S. has set its own targets for reducing CO2 emissions, aligning with international goals to combat climate change. By investing in cleaner energy sources and sustainable practices, we not only protect our planet but also ensure safer working environments for future generations. At HJ3, we believe that progress in technology should go hand-in-hand with a commitment to environmental responsibility. Our efforts in developing robust carbon fiber materials are just one part of a larger strategy to make industries more sustainable while safeguarding the people who work within them. Together, we can build a future where mining is not only safer but also environmentally conscious. While the road ahead is filled with challenges, the strides we’ve made in recent years give us hope. From implementing advanced proximity detection systems to advocating for cleaner energy policies, every step counts. Let’s continue to innovate and strive for a world where safety and sustainability go hand-in-hand. vape Assembly Equipment,vape Accessories Assembly Machine,vape Needle Insertion Machine,vape Assembly Machine Shenzhen Yonglun Intelligent Equipment Technology Co., LTD , https://www.foyooo.com